Pre-recorded Sessions: From 4 December 2020 | Live Sessions: 10 – 13 December 2020

4 – 13 December 2020

Pre-recorded Sessions: From 4 December 2020 | Live Sessions: 10 – 13 December 2020

4 – 13 December 2020

#SIGGRAPHAsia | #SIGGRAPHAsia2020

#SIGGRAPHAsia | #SIGGRAPHAsia2020

Date: Friday, December 11th

Time: 12:30pm - 1:00pm

Venue: Zoom Room 4

Note: All live sessions will be screened on Singapore Time/GMT+8. Convert your time zone here.

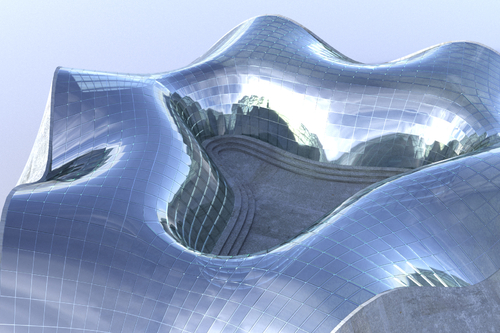

Abstract: Cold bent glass is a promising and cost-efficient method for realizing doubly curved glass façades. They are produced by attaching planar glass sheets to curved frames and require keeping the occurring stress within safe limits. However, it is very challenging to navigate the design space of cold bent glass panels due to the fragility of the material, which impedes the form-finding for practically feasible and aesthetically pleasing cold bent glass façades. We propose an interactive, data-driven approach for designing cold bent glass façades that can be seamlessly integrated into a typical architectural design pipeline. Our method allows non-expert users to interactively edit a parametric surface while providing real-time feedback on the deformed shape and maximum stress of cold bent glass panels. Designs are automatically refined to minimize several fairness criteria while maximal stresses are kept within glass limits. We achieve interactive frame rates by using a differentiable Mixture Density Network trained from more than a million simulations. Given a curved boundary, our regression model is capable of handling multistable configurations and accurately predicting the equilibrium shape of the panel and its corresponding maximal stress. We show predictions are highly accurate and validate our results with a physical realization of a cold bent glass surface.

Author(s)/Presenter(s):

Konstantinos Gavriil, TU Wien, Austria

Ruslan Guseinov, Institute of Science and Technology Austria, Austria

Jesus Perez, URJC Madrid, Spain

Davide Pellis, TU Wien, Austria

Paul Henderson, Institute of Science and Technology Austria, Austria

Florian Rist, King Abdullah University of Science and Technology (KAUST), Saudi Arabia

Helmut Pottmann, King Abdullah University of Science and Technology (KAUST), Saudi Arabia

Bernd Bickel, Institute of Science and Technology Austria, Austria

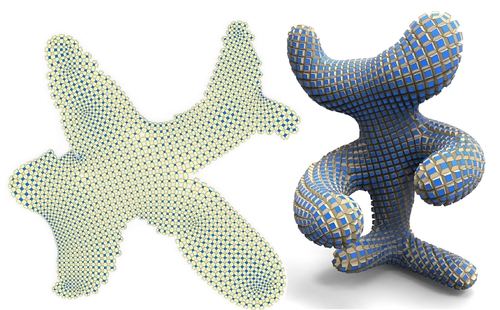

Abstract: Kirigami, the traditional Japanese art of paper cutting and folding generalizes origami and has initiated new research in material science as well as graphics. In this paper we use its capabilities to perform geometric modeling with currogated surface representations possessing an isometric unfolding into a planar domain after appropriate cuts are made. We initialize our box-based kirigami structures from orthogonal networks of curves, compute a first approximation of their unfolding via mappings between meshes, and complete the process by global optimization. Besides the modeling capabilities we also study the interesting geometry of special kirigami structures from the theoretical side. This experimental paper also strives to relate unfoldable checkerboard arrangements of boxes to principal meshes, to the transformation theory of discrete differential geometry, and to a version of the Gauss theorema egregium.

Author(s)/Presenter(s):

Caigui Jiang, KAUST, Saudi Arabia

Florian Rist, KAUST, Saudi Arabia

Helmut Pottmann, KAUST, Saudi Arabia

Johannes Wallner, TU Graz, Austria

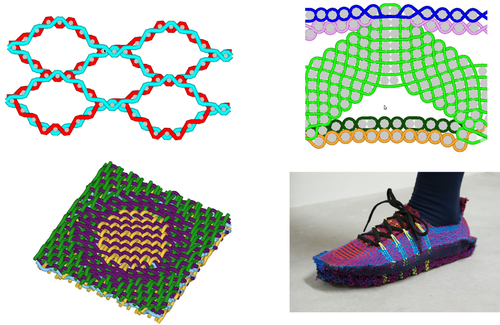

Abstract: 3D weaving is an emerging technology for manufacturing multilayer woven textiles. In this work, we present Weavecraft: an interactive, simulation-based design tool for 3D weaving. Unlike existing textile software that uses 2D representations for design patterns, we propose a novel weave block representation that helps the user to understand 3D woven structures and to create complex multi-layered patterns. With Weavecraft, users can create blocks either from scratch or by loading traditional weaves, compose the blocks into large structures, and edit the pattern at various scales. Furthermore, users can verify the design with a physically based simulator, which predicts and visualizes the geometric structure of the woven material and reveals potential defects at an interactive rate. We demonstrate a range of results created with our tool, from simple two-layer cloth and well known 3D structures to a more sophisticated design of a 3D woven shoe, and we evaluate the effectiveness of our system via a formative user study.

Author(s)/Presenter(s):

Rundong Wu, Cornell University, United States of America

Joy Xiaoji Zhang, Cornell University, United States of America

Jonathan Leaf, Stanford University, United States of America

Xinru Hua, Stanford University, United States of America

Ante Qu, Stanford University, United States of America

Claire Harvey, T.E.A.M. Inc., United States of America

Emily Holtzman, Rhode Island School of Design, United States of America

Joy Ko, Rhode Island School of Design, United States of America

Brooks Hagan, Rhode Island School of Design, United States of America

Doug James, Stanford University, United States of America

François Guimbretière, Cornell University, United States of America

Steve Marschner, Cornell University, United States of America

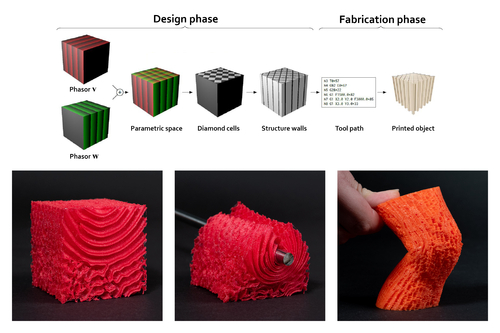

Abstract: Nature offers a marvel of astonishing and rich deformation behaviors. Yet, most of the objects we fabricate are comparatively rather inexpressive, either rigid or exhibiting simple homogeneous deformations when interacted with. We explore the synthesis and fabrication of novel microstructures that mimic the effects of having oriented rigid fibers in an otherwise flexible material: the result is extremely rigid along a transverse direction while being comparatively very flexible in the locally orthogonal plane. By allowing free gradation of the rigidity direction orientation within the object, the microstructures can be designed such that, under deformation, distances along fibers in the volume are preserved while others freely change. Through a simple painting tool, this allows a designer to influence the way the volume reshapes when deformed, and results in a wide range of novel possibilities. Many gradations are possible: local free orientation of the fibers; local control of the overall material rigidity (structure density); local canceling of the effect of the fibers, obtaining a more isotropic material. Our algorithm to synthesize the structures builds upon procedural texturing. It produces a cellular geometry that can be fabricated reliably despite 3D printing walls at a minimal thickness, allowing prints to be very flexible. The synthesis algorithm is efficient, and scales to large volumes.

Author(s)/Presenter(s):

Thibault Tricard, I.N.R.I.A. Nancy, University of Lorraine, France

Vincet Tavernier, INRIA, France

Cedric Zanni, University of Lorraine, France

Jonàs Martínez, INRIA, France

Pierre-Alexandre Hugron, INRIA, France

Fabrice Neyret, INRIA, France

Sylvain Lefebvre, INRIA, France

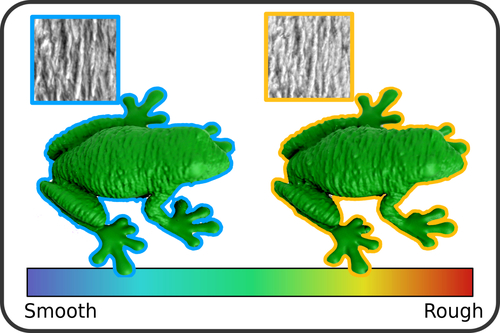

Abstract: Textures are encountered often on various common objects and surfaces. Many textures combine visual and tactile aspects, each serving important purposes; most obviously, a texture alters the object's appearance or tactile feeling as well as serving for visual or tactile identification and improving usability. The tactile feel and visual appearance of objects are often linked, but they may interact in unpredictable ways. Advances in high-resolution 3D printing enable highly flexible control of geometry to permit manipulation of both visual appearance and tactile properties. In this paper, we propose an optimization method to independently control the tactile properties and visual appearance of a texture. Our optimization is enabled by neural network-based models, and allows the creation of textures with a desired tactile feeling while preserving a desired visual appearance at a relatively low computational cost, for use in a variety of applications.

Author(s)/Presenter(s):

Chelsea Tymms, New York University, United States of America

Siqi Wang, New York University, United States of America

Denis Zorin, New York University, United States of America