Pre-recorded Sessions: From 4 December 2020 | Live Sessions: 10 – 13 December 2020

4 – 13 December 2020

Pre-recorded Sessions: From 4 December 2020 | Live Sessions: 10 – 13 December 2020

4 – 13 December 2020

#SIGGRAPHAsia | #SIGGRAPHAsia2020

#SIGGRAPHAsia | #SIGGRAPHAsia2020

Date/Time:

04 – 13 December 2020

All presentations are available in the virtual platform on-demand.

Lecturer(s):

Jinfan Yang, University of British Columbia, Canada

Chrystiano Araújo, University of British Columbia, Canada

Nicholas Vining, University of British Columbia, Google Inc., Canada

Zachary Ferguson, New York University, United States of America

Enrique Rosales, University of British Columbia, Universidad Panamericana, Canada

Daniele Panozzo, New York University, United States of America

Sylvain Lefebvre, French Institute for Research in Computer Science and Automation, France

Paolo Cignoni, Institute for Computer Science and Technologies - Italian National Research Council, Italy

Alla Sheffer, University of British Columbia, Canada

Bio:

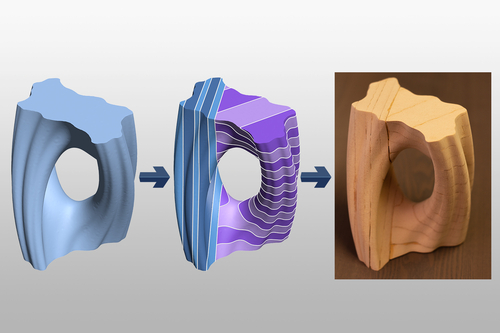

Description: Milling objects from precut slabs of materials such as wood or stone using a 3-axis mill is an appealing, cheap, and precise fabrication technique. However, a 3-axis mill can only carve a height-field (HF) surface during each milling pass, limiting the space of directly millable shapes. Moreover, the size of millable shapes is bounded by the slab dimensions. For most pre-cut materials, one of these dimensions, the height, is typically significantly smaller than the others. Extending 3-axis milling of pre-cut slabs to general arbitrarily-sized shapes requires decomposing them into bounded-height 3-axis-millable and assemblable parts, or slices, which can be individually milled and then assembled to form the target object. We present DHFSlicer, a novel decomposition method that satisfies the above constraints and significantly reduces both milling time and material waste compared to alternative approaches. We satisfy the fabrication constraints by partitioning shapes into bounded-height double-height-field (DHF) slices, which can be fabricated using two milling passes: the HF surface accessible from one side is milled first, the slice is then flipped using appropriate fixtures, and then the second, remaining, HF surface is milled. DHFSlicer uses an efficient coarse-to-fine process to produce DHF slices that satisfy all fabrication constraints. It first partitions the inputs into maximally coarse blocks that satisfy a local DHF criterion with respect to per-block milling axes, and then cuts each block into well-sized DHF slices. It minimizes milling time and material waste by keeping the slice count small, and maximizing slice height. We enable an end-to-end DHF slice-based fabrication pipeline by automatically computing suitable fabrication fixtures and validate it by fabricating objects from slabs of foam, wood, and MDF. We demonstrate that using our slices reduces milling time and material waste by 42% on average compared to existing automatic alternatives; and highlight its benefits via extensive ablation studies.